This summer, I'm spending eight weeks working at the MagLab's Applied Superconductivity Center. My mentor is Jeremy Weiss, a graduate research assistant.

Encouraged by my research mentor in Puerto Rico, Professor Marcelo Suárez, I browsed through the website of the REU program at the National High Magnetic Field Laboratory. I became extremely excited to have found research opportunities that can help me gain more expertise in advanced materials science and engineering. For this reason, I decided to apply. Currently, my work is to determine the superconducting properties (such as critical temperature, volumetric susceptibility, magnetization and critical current density) for wires made of two superconducting materials: cobalt-doped barium 122 and potassium-doped barium 122, heat-treated at low temperatures (300 degrees Centigrade to 700 degrees C) with no external pressure.

The machines I use for my research in the MagLab are a two-zone furnace and a differential temperature analyzer (DTA). At the Shaw building, I use even more machines and tools: the sagging machine, the fume box, glove box, cutting machine, polishing machines, optical microscopes, scanning electron microscope (SEM), and the superconducting quantum interference device (SQUID).

One of the most difficult things in my project has been that the samples are heat-treated at a progressive state. So, if you start at 300 degrees C, you measure the sample's properties and continue ramping up the temperature. But if you are supposed to finish at 650 degrees C, and you damage your sample at 550 degrees C, you basically lose a whole month of work and have to start all over again! Thus, I had to double-check every time I heat-treated my samples so that wouldn't happen.

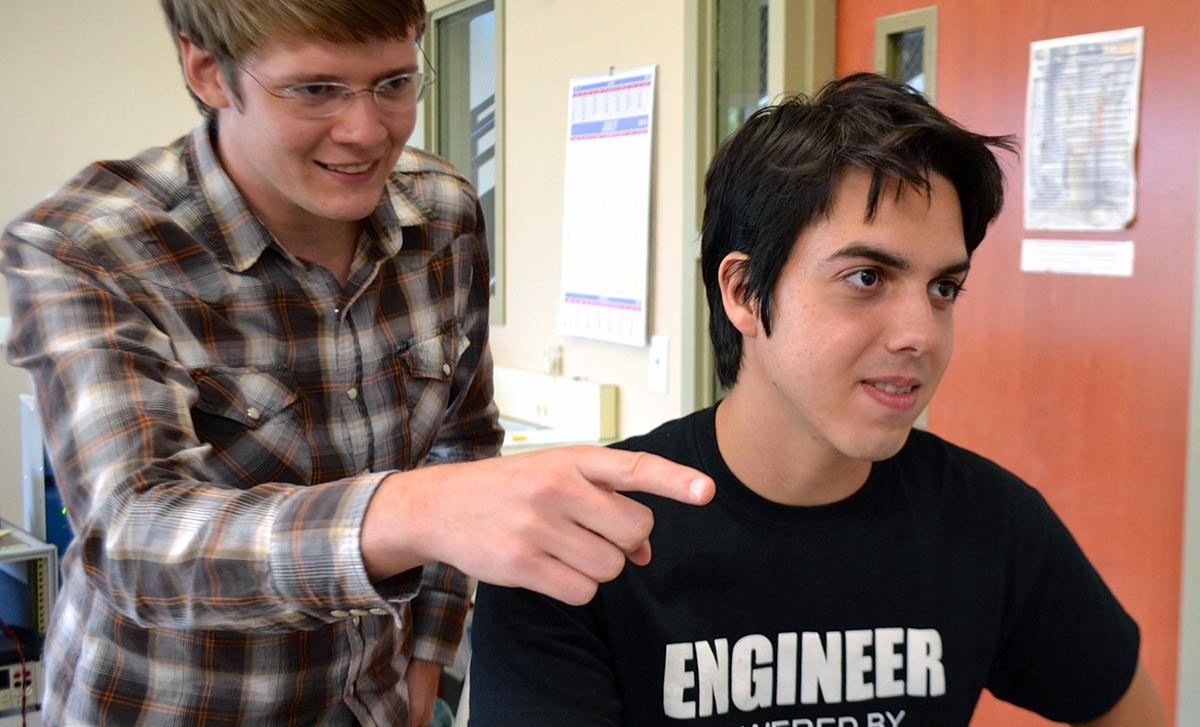

I realized during this internship how much I like to do research and how gratifying it is to see that something is happening when you plot the data acquired. A funny time I remember at my internship here was when I used the torch for the first time. I was quite afraid, since I'm not used to using torches, but Jeremy was like, "turn up the fire a little more, because we cannot make a capsule with that fire." I didn't listen, though, because I was afraid I would damage the sample. It took so much time to make the capsule, and I was thinking, "Why isn't it melting faster?" But the next sample, I did turn up the heat and everything was all right.

Because Jeremy and I are close in age (Jeremy is 27), I can be more myself and say things more like I would normally say them. I have got to say thanks to him because I really appreciate his help. Before I got here, I was intimidated. But after I got here, I was excited. Jeremy has been really easy to talk to, and he explains things to me until I understand. We've had more of a one-on-one experience, which lets you get to know each other better and communicate better, which leads to having a better working environment.

Before I got here, I liked mostly ceramics, but now that I have worked with superconductors, I have to say it's exciting working with them. I like working to make the properties of a material better, or to make something new. I'm proud of the moment when I look back at all the work I've done from my graphs and say: "Yeah, I made this happen."

I will remember the MagLab as a place I liked a lot, and a place where I learned a lot. I would like Jeremy to remember me as a hard-working REU student — and as a guy you can always hang out with, and that would be happy to show him around my island any time.

By Kathleen Laufenberg