There had to be a better way. That's what Lee Marks, a MagLab research engineer, thought every time he watched it happen. Technicians had to stop building a powerful 35-tesla hybrid magnet so someone could manually wrap insulating tape around a 40-foot stretch of cable. The task, which was tedious but critical, took at least 30 minutes.

"It was a real time-waster," Marks said. "It was throwing everything off schedule."

So Marks and a co-worker did what engineers and technicians often do at the lab: They brainstormed solutions until they came up with an idea they thought would work. In this case, their clever problem solving would later win them both well-deserved recognition and two awards.

Dream machine

Marks guessed that there was probably a machine available somewhere that could do the manual tape-winding task for them. So he and fellow engineer Tom Painter looked and Googled, but ultimately came up with nada.

Lee Marks (left) and Scott Bole with the machine they invented.

"there just wasn't a machine out there that really did what we wanted," said Marks, who has been at the lab for 15 years. "So I came up with an idea and scribbled out something."

Marks showed his drawings — penciled onto the back of a couple of sheets of graph paper — to engineer Scott Bole.

"Lee kept putting the bug in my ear: 'We got to do something about this,'" said Bole, who has worked at the lab for 19 years. "He was kind of the spearhead of the whole thing, and I was kind of the enabler. I just did the mechanics: figured out the sizes of everything, the nuts and bolts stuff."

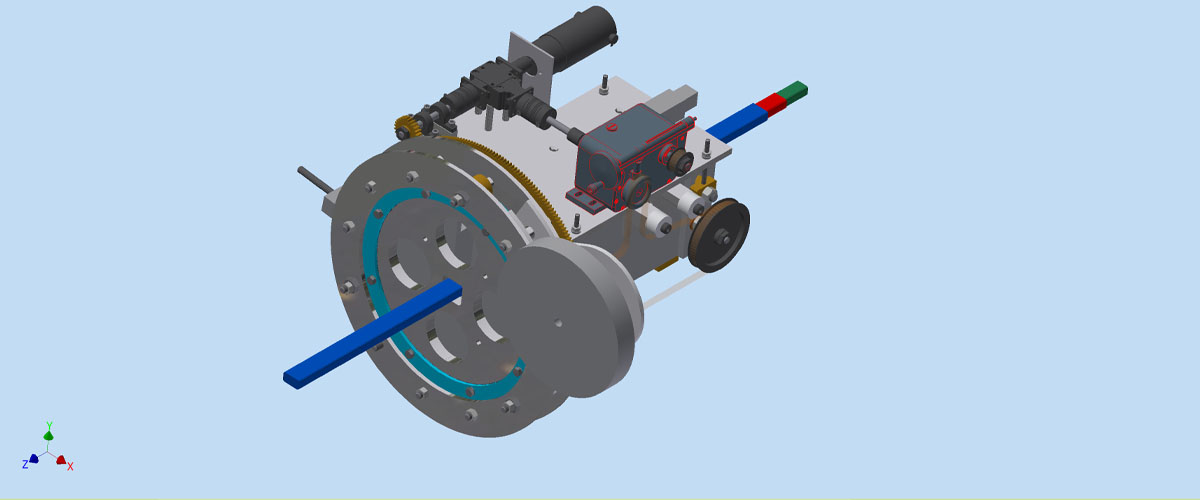

Over the stretch of four to five months, Scott designed a machine — weighing about 100 pounds and powered by a small DC motor — to wind the insulating tape around the cable. Then they took it out for a trial run.

Sly solution

"We just turned the switch on and it worked," Bole said. "I've designed a lot of rotating machinery in my career, but I don't know of any other machine that I've designed that we just flipped the switch and it worked. There's always some little glitch. So that was pretty amazing."

For flair, they attached an orange and yellow flame logo onto their invention with its official, patent-pending name: Automated Insulation Machine. But Nichole Walsh, a lab assistant who helps build new magnets, has another moniker for it.

"I call it a lifesaver," Walsh said. "It streamlines everything."

The new machine quickly and accurately winds the tape, and the magnet-building team no longer has to stop working. But wait: There's even a dab of whipped cream to top off this already sweet story.

"The best part about this whole job," Bole said, "is that we did it in skunk works mode."

Say whaaat? Skunk works mode?

"That means you're doing it in secret; you don't tell anybody, you just show up one day and say 'Look what we got!' We weren't given the job to do this, we just saw the need and in our spare time, we put this thing together."

Drum roll please

Lee Marks' conceptual drawing led to Scott Bole's AutoCAD design (above) of a money- and time-saving machine that winds tape around superconducting cable.

While creative problem solving is frequently part of a day's work at the lab, this time it won special kudos for Bole and Marks. Creating the machine earned them a 2012 Davis Productivity Award and a 2012 Jeffrey Gabor Superior Accomplishment Award.

Florida State University gives the Gabor award, which comes with a $500 savings bond, to exemplary employees. The Davis award recognizes state employees whose work increases productivity and promotes innovation. The Davis award is co-sponsored by Florida TaxWatch, the Florida Council of 100 and the state of Florida, and its winners are honored at a banquet.

"Scott and Lee never cease to impress," said Mark Bird, director of the lab's Magnet Science &Technology. "They're constantly developing new and excellent ideas, and implementing them, ultimately saving everyone some time and money."

This story was originally published in Issue 9 of flux magazine, a discontinued publication of the National High Magnetic Field Laboratory.

By Kathleen Laufenberg