November 14, 2024

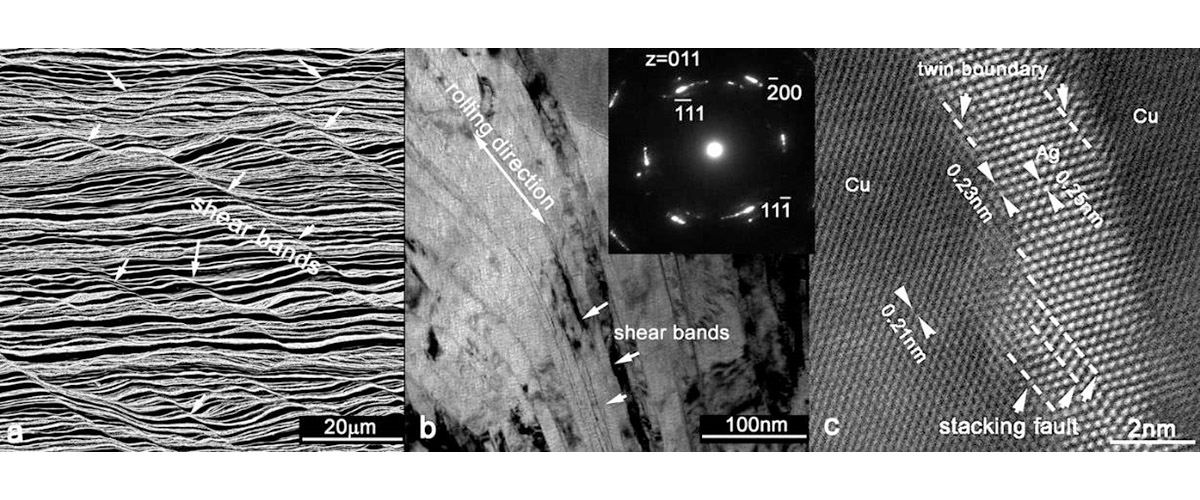

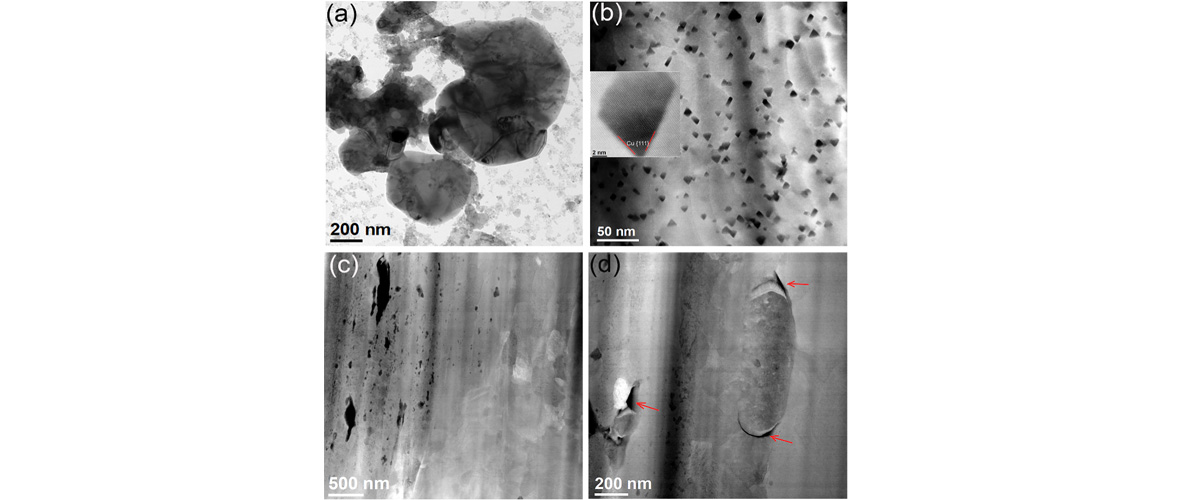

Because of such desirable properties as high mechanical strength and electrical conductivity, Cu–Ag nano-structured sheets are used, not only in high …

October 14, 2024

Because of such desirable properties as high mechanical strength and electrical conductivity, Cu–Ag nano-structured sheets are used, not only in high …

May 15, 2024

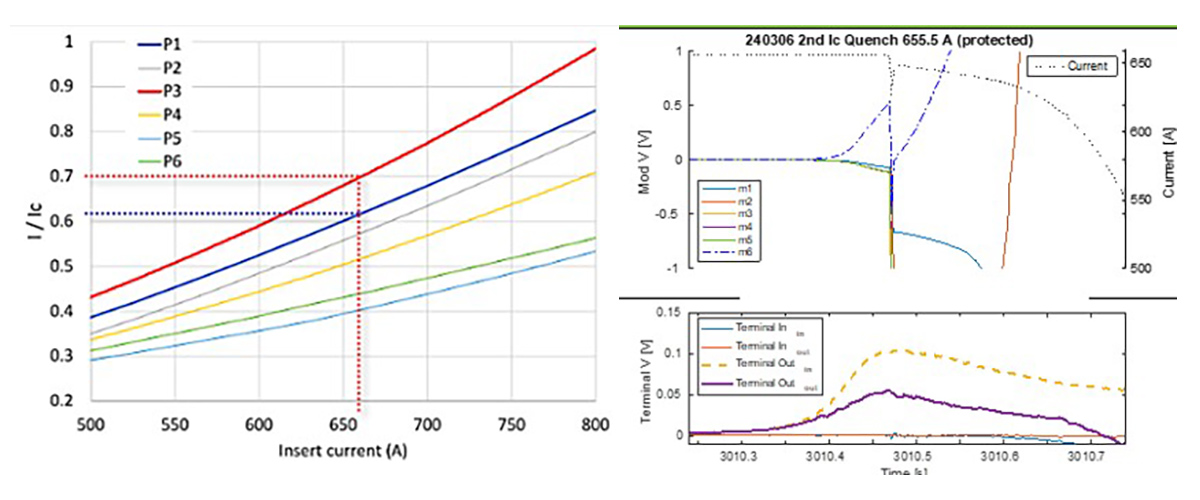

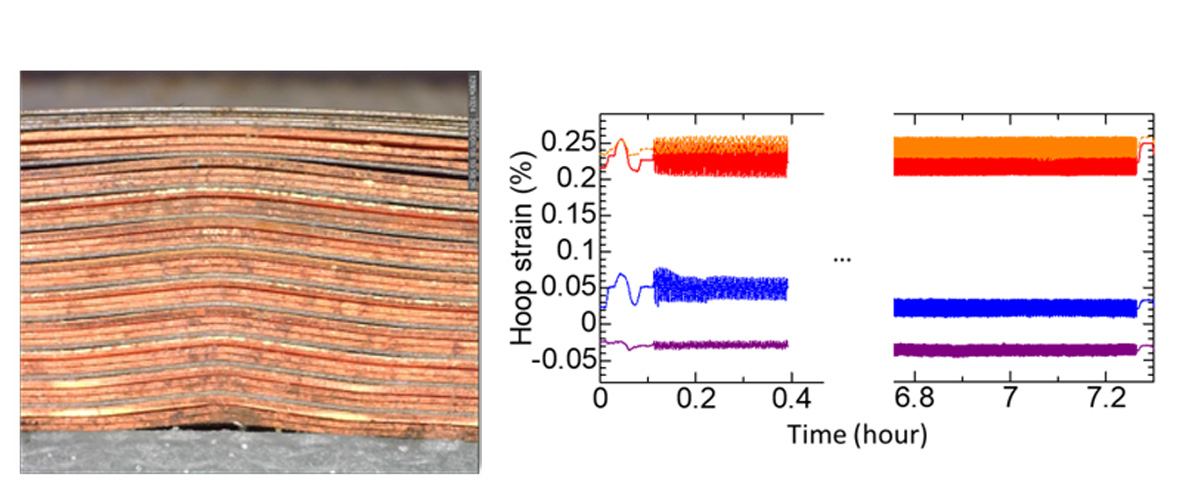

High-temperature superconducting test coils have been subjected to extreme combined loads from high, cyclic pressure and electro-magnetic forces to un…

December 15, 2023

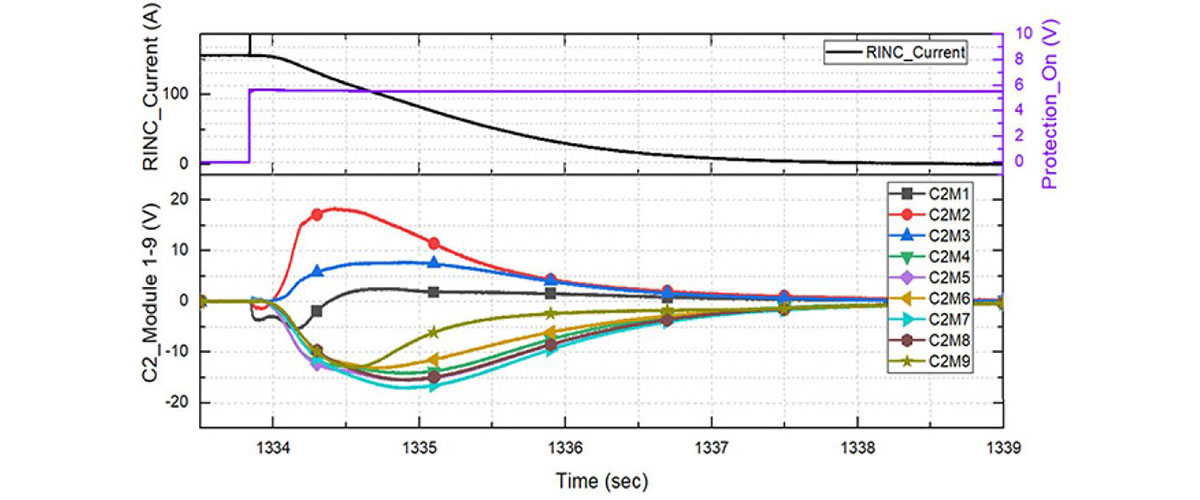

A test protocol has been developed and successfully demonstrated the ability to evaluate the performance of a large percentage of tape in a REBCO-woun…

May 24, 2023

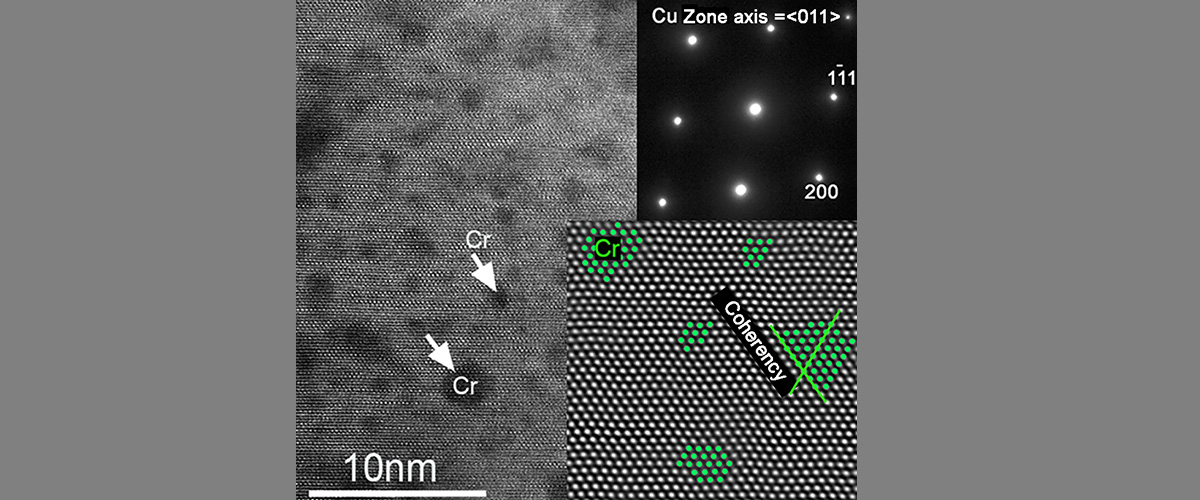

MagLab researchers developed a way to make a Copper-Chromium-Zirconium conductor for pulsed magnets that has tiny particles evenly distributed through…

December 12, 2022

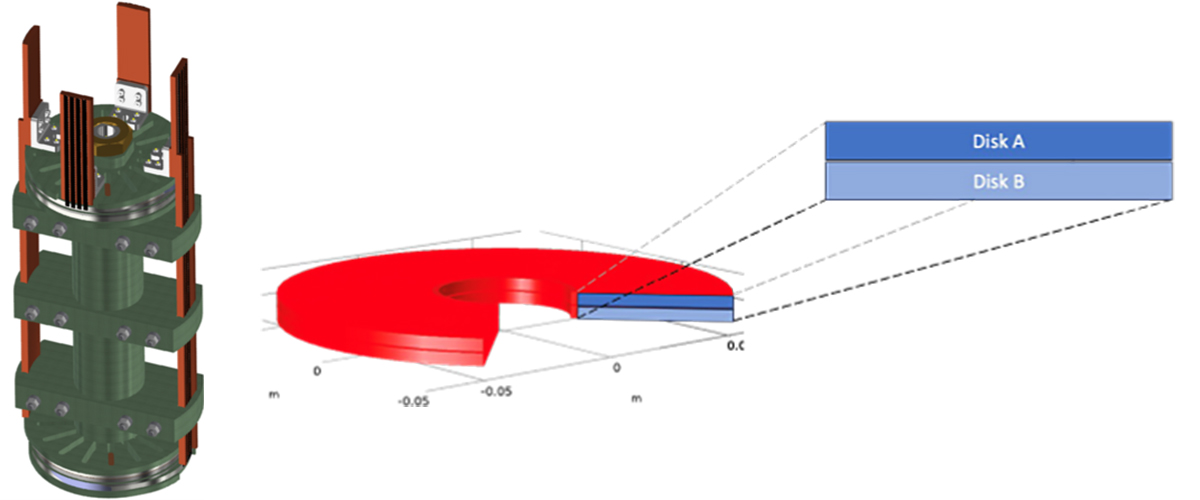

A 19 T high-field magnet made with REBCO high-temperature superconductor, but without electrical insulation, was tested to see if it is a viable desig…

August 15, 2022

The MagLab's ultrahigh-field pulsed magnets require materials with both high mechanical strength and high electrical conductivity. One of these materi…

August 20, 2021

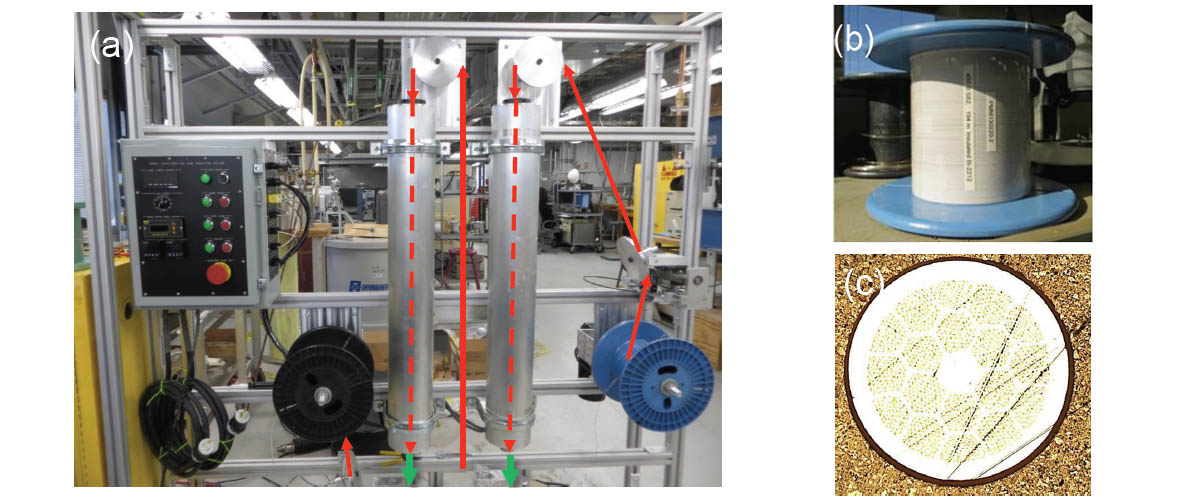

A new device enables the testing of superconducting cables to high current without the high helium consumption associated with traditional current lea…

February 11, 2021

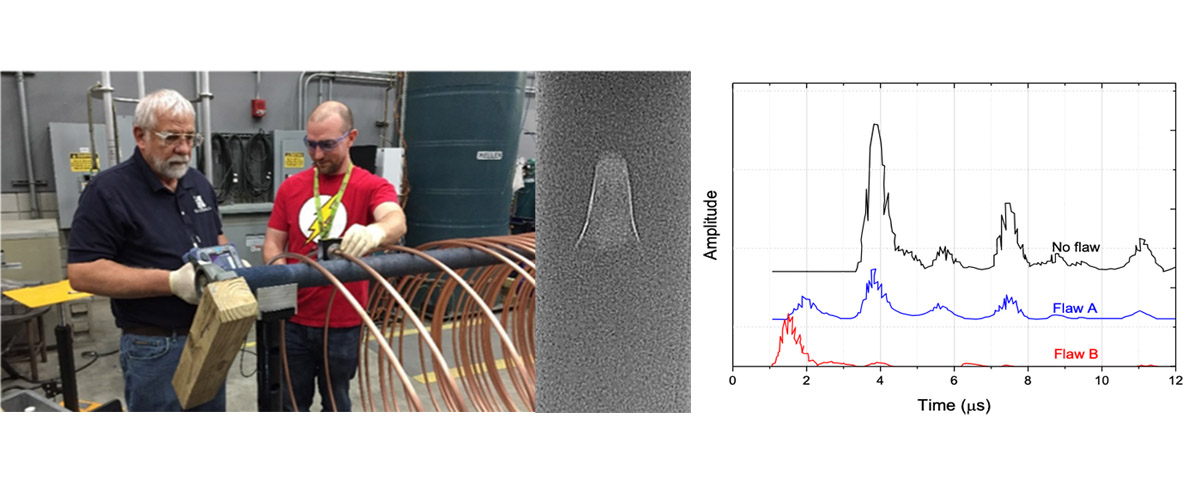

Three non-destructive testing methods are developed for inspection of high strength, high conductivity wires which are used to wind ultra-high field p…

January 19, 2021

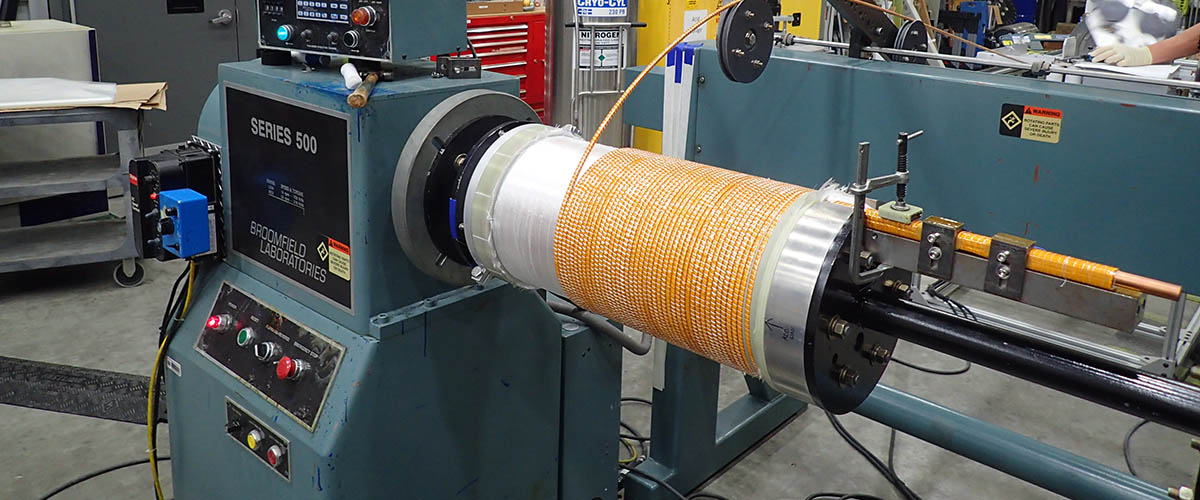

A recent test coil with more than 1300 meters of conductor successfully demonstrated a new winding technique for insulated REBCO technology and was fa…

June 23, 2020

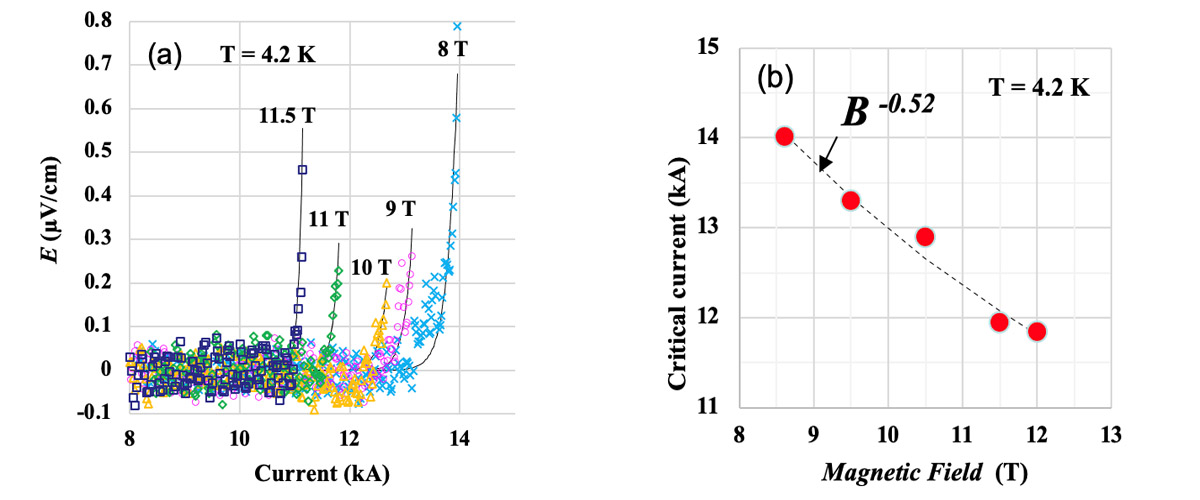

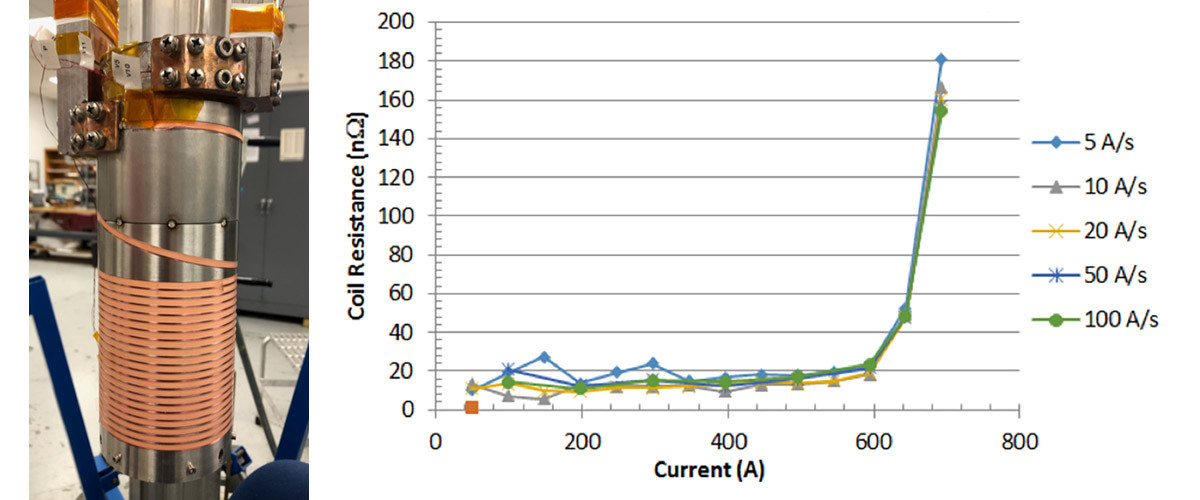

Tests of the first Integrated Coil Form test coil wound using REBCO superconducting tape show promise for use in ultra powerful magnets of the future.

April 23, 2020

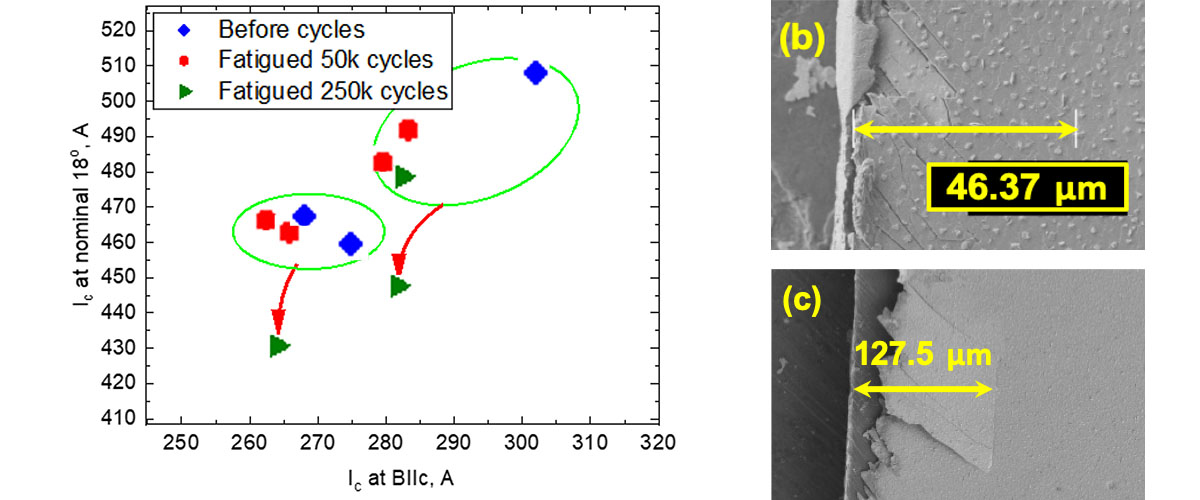

Tests of high-temperature superconducting REBCO tapes at 4.2 K showed resistance to cyclic loading, demonstrating that it is a promising material for …

April 10, 2019

Pulsed magnets are designed to operate near their structural limits to be able to generate extremely high magnetic fields. The coils have a limited li…

March 19, 2018

MagLab scientists and engineers have developed a special coating on Bi-2212 superconducting wire for electrical insulation in superconducting magnets …