What is the finding?

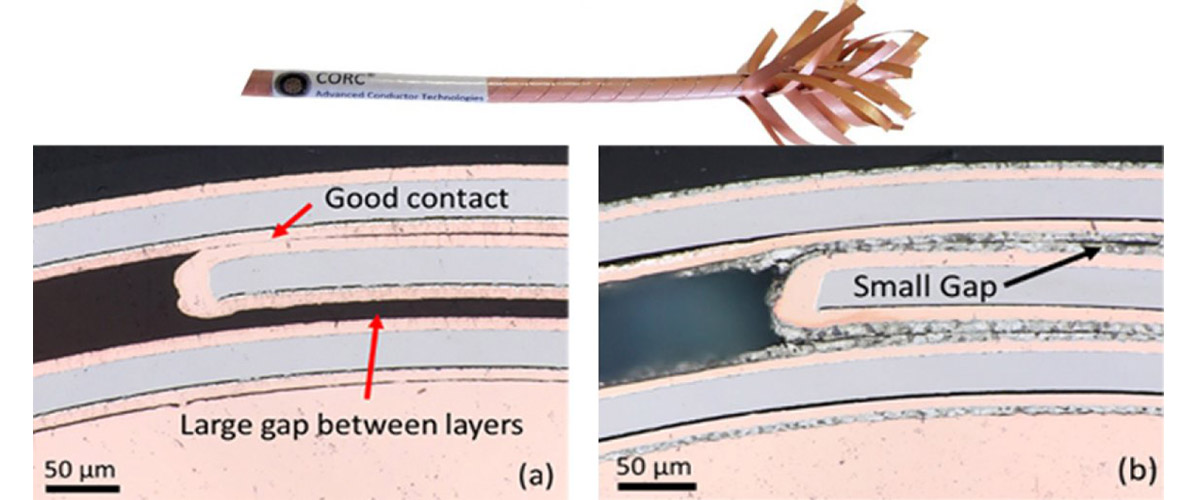

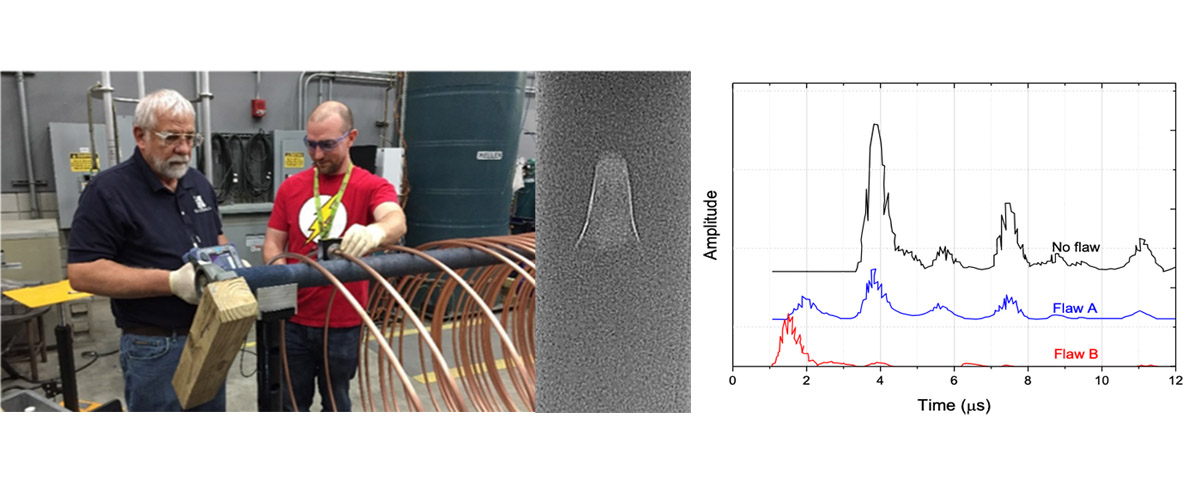

Here cross-sectional images of superconducting Conductor on Round Core (CORC®) wires (Figure 1 - top image) revealed insights to improve the contact between conductors after noticing arge regions without contact in typical cables (Figure 2a - bottom left), leading to a high resistance between conductors. insights to improve the contact between conductors. Led by a graduate student researcher, this work shows how the details of how the conductors overlap affects the switching ability in the cable, finding that a little solder works very well even without heating the solder to melt it.

Why is this important?

In magnets, one of the biggest concerns is that a localized area of degraded conductor may lead to hot spot formation and cause irreversible damage to the magnet. The ability for current to transfer between conductors - and thereby bypass degraded conductor regions - minimizes the chances of conductor burnout. In CORC® cables, current transfer depends on the contact resistance between layers. Winding wires from PbSn tinned tapes provides more uniform contact between layers (Figure 2b - bottom right), decreasing the contact resistance by three orders of magnitude and yielding a cable that is more resistant to burnout.

Who did the research?

V. Phifer1,2, M. Small1,2 , G. Bradford1,2, J. Weiss3,4, D. van der Laan3,4 and L. Cooley1,2

1Florida Sate University; 2Applied Superconductivity Center-MagLab; 3Advanced Conductor Technologies

Why did this work need the MagLab?

The MagLab's Applied Superconductivity Center hosts unique expertise on superconducting materials. The imaging and resistivity measurements reported here were coupled with electromagnetic measurements like those used for MagLab's 32T superconducting magnet.

Details for scientists

- View or download the expert-level Science Highlight, The high temperature superconducting CORC® cabling technology

Funding

This research was funded by the following grants: G.S. Boebinger (NSF DMR-1644779); S. Pamidi (DE-EE0007872); D. Larbalestier (DE-SC0014009)

For more information, contact Lance Cooley.